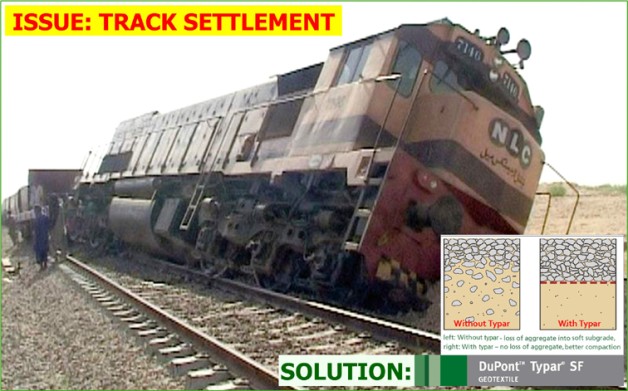

New Railway track and tracks renewal

Railway track is areas with soft soils and high ground water levels are susceptible to settlement and requires regular maintenance for track alignment and safe transportation. Typar SF below ballast provides stabilization and separation to reduce impact of dynamic loading.

- Typar SF avoids ballast contamination by pumping effect due to dynamic loading.

- It allows better compacting and aggregate saving.

- Typar SF retains soil particles without clogging.

- It ensures longer service life.

Separation

In geotextile applications, separation is defined as: “The preventing from intermixing of adjacent dissimilar soils and/or fill materials by the use of a geotextile or a geotextile-related product”5 .

The main application areas of a geotextile used as a separator are in road and railway projects. The use of the geotextile preserves and improves the integrity and function of the different materials.

Firstly, the geotextile prevents the loss of aggregate into the soft subgrade (Fig. 4). An engineering adage describes this very well:

“10 kilos of stone placed on 10 kilos of mud results in 20 kilos of mud”. The geotextile separates and confines the aggregate base course, so that a higher degree of compaction can be obtained.

Secondly, the contamination of the aggregate base by the subgrade soil is prevented and a reduction of the bearing capacity avoided. The migration of fine soil particles into the clean aggregate occurs especially under dynamic loading and can be

described as a “pumping effect”. The fines act as a lubricant between the coarse aggregate particles and can so substantially reduce the shear strength of the aggregate.

Also, an uncontaminated aggregate will continue to effectively perform in its drainage function as well as maintain a higher resistance to frost-heave effects.